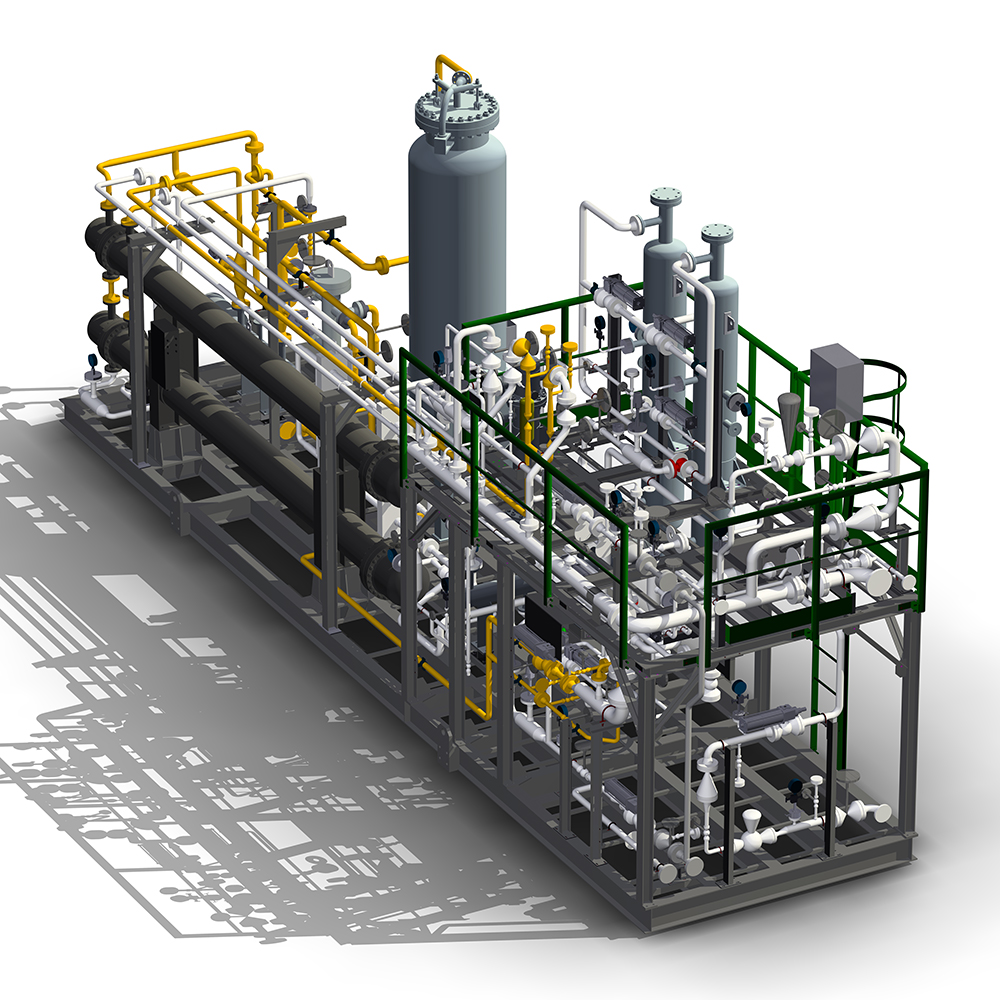

Hydrogen purification units

In its commitment to a more sustainable world, VLV has decided to enter the green and blue hydrogen market sharing the long time experience matured in the oil and gas field, where grey hydrogen is widely produced. In particular VLV has been focusing on the hydrogen purification packages, bringing the knowledge gained in refineries and petrolchemical plants to the new upcoming market of the sustainable hydrogen, offering turn key solutions for hydrogen purification, based on different hydrogen sources and hydrogen contaminants.

What we provide?

Depending on the hydrogen source and the user requirements, VLV can provide a variety of different treatments.

As a result of the treatments cycle, Hydrogen with a purity up to 99,9995% can be produced, suitable to be used for fuel cells, high pressure storage and for many more applications.

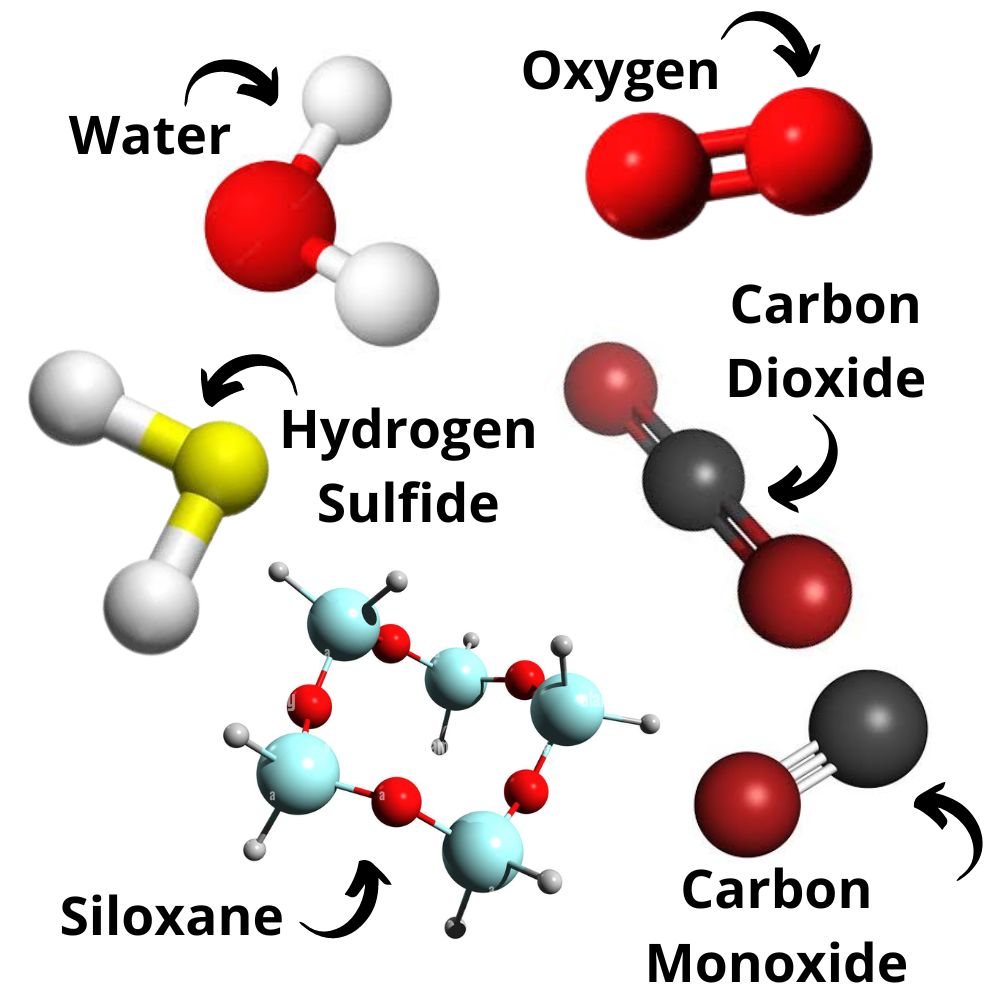

Different sources may produce different gas mixtures with Hydrogen in a purity ranging from 20% up to more than 99%; depending on the component that need to be separated and on the concentration levels, a different treatment may be required.

VLV can design different process flows, depending on the inlet gas conditions, to remove Hydrogen pollutants such as:

Water

Oxygen

Hydrogen Sulfide

Carbon Dioxide

Carbon Monoxide

Siloxane

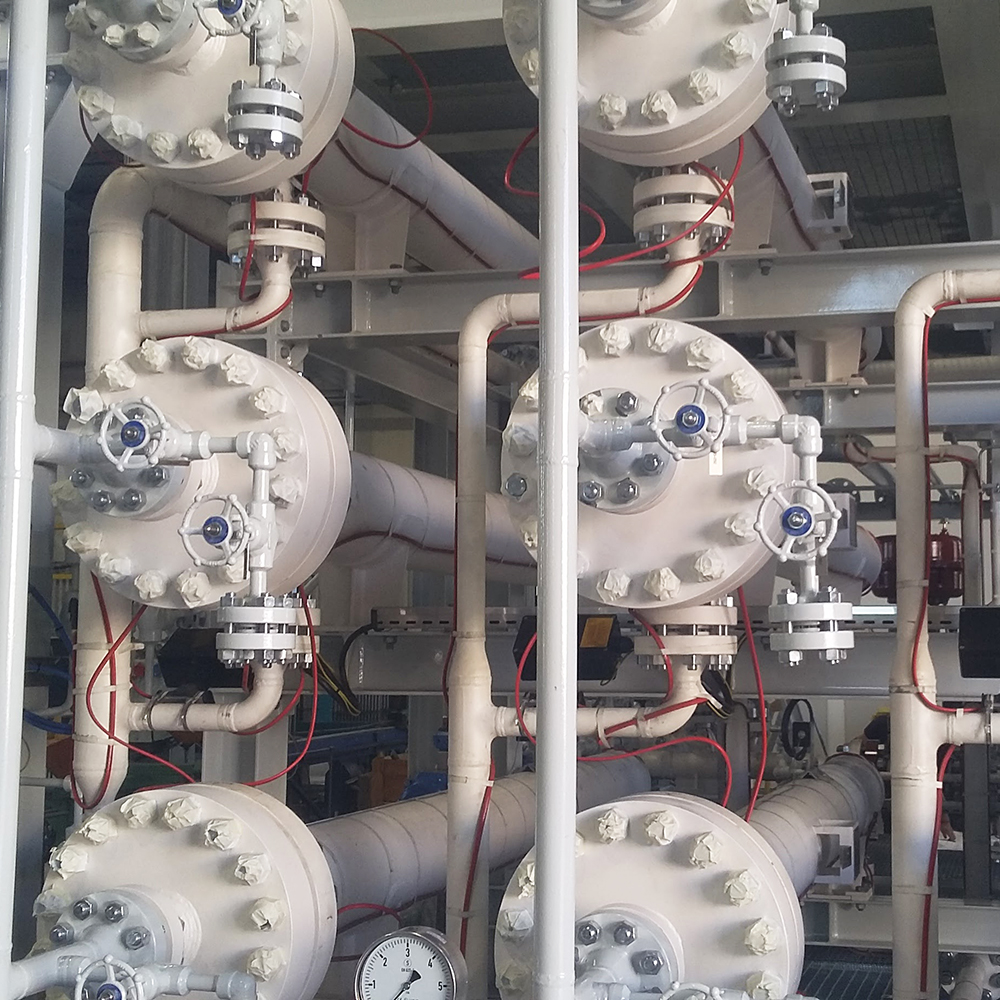

VLV provides units based on the following technologies:

Non-regenerative adsorbtion

Whenever the initial gas mixture is not so rich in hydrogen content and the flow conditions are suitable for it, VLV units include a pre-treatment system based on selective membranes.

This system allows an energy efficient first recovery of hydrogen, with the consequent reduction in the purification Capex and Opex.

In the picture: membranes hollows fiber (not spaghetti).