Column internals

VLV deals with the supply of columns internals: from valve trays to liquid distributors to custom support grids, each product is always designed according to specific customer needs.

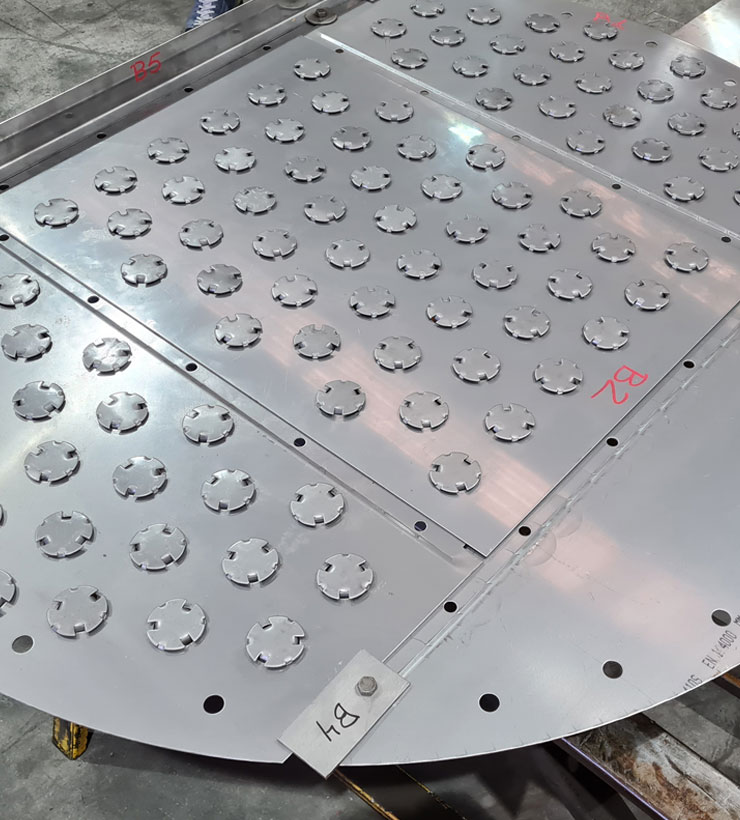

VALVE TRAYS

Valve trays are mainly used in distillation plants and to optimize the thermodynamic balance between the liquid and gaseous phase.

The trays consist of a perforated surface and are equipped with devices that put the two phases in contact, a zone called descending, where the liquid flow drops from the upper plate, and an area where the liquid passes to the lower plate.

Greater liquid-vapour contact leads to better separation on each tray and thus greater column efficiency.

Contact devices are mainly of the following types:

fixed valve trays

trays with bell valves

mobile valve trays

VLV performs the dimensioning and complete engineering of these internals, starting from the customer’s needs.

LIQUID DISTRIBUTORS

The liquid distributors are positioned inside the process columns and are necessary to ensure a correct distribution of the liquid flow.

In columns, a bed of structured bodies is often used that can facilitate the desired process.

VLV sizes and manufactures these internals optimizing them according to the needs of the process.

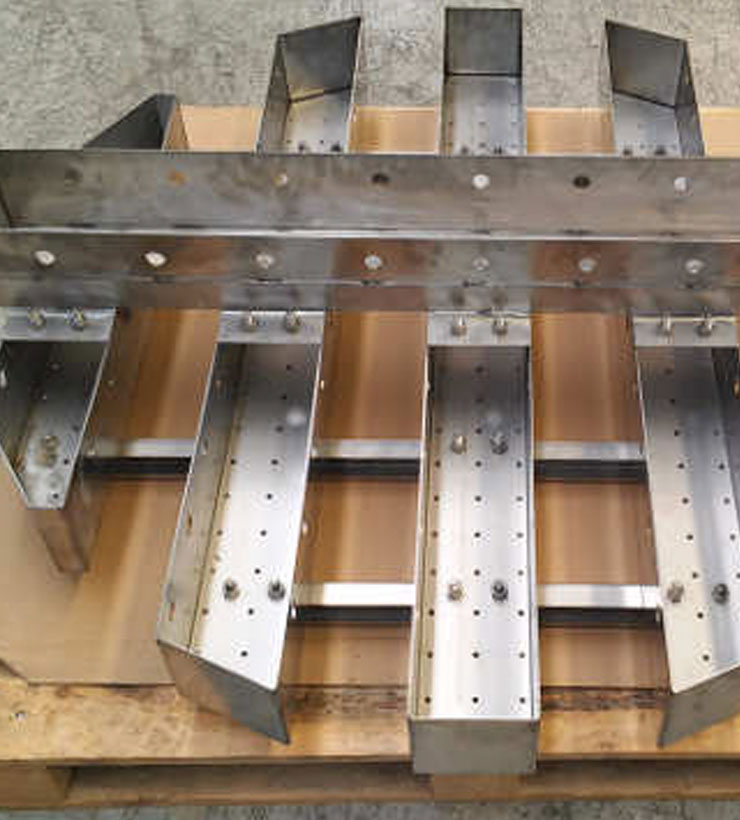

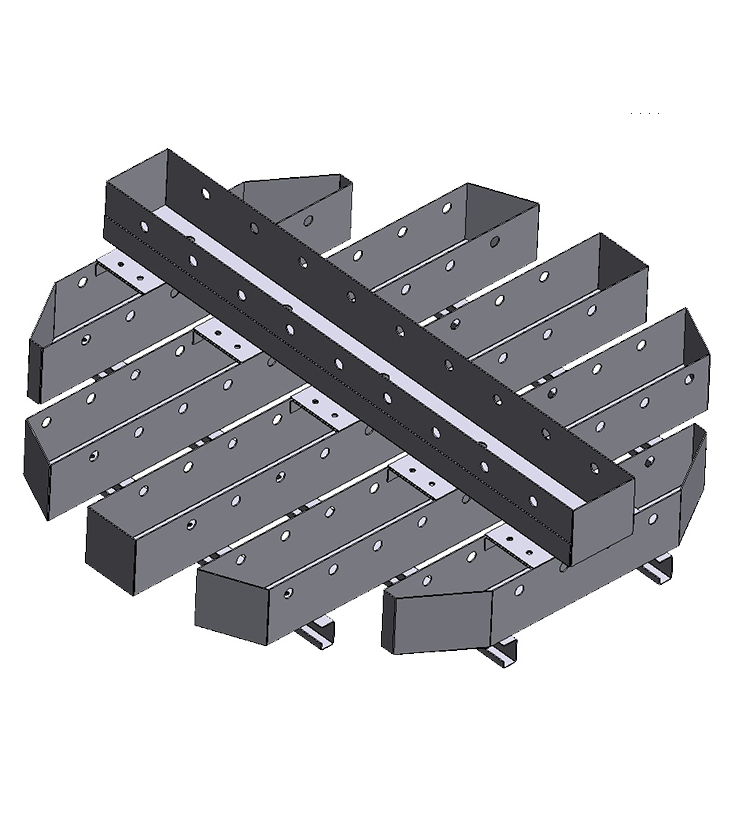

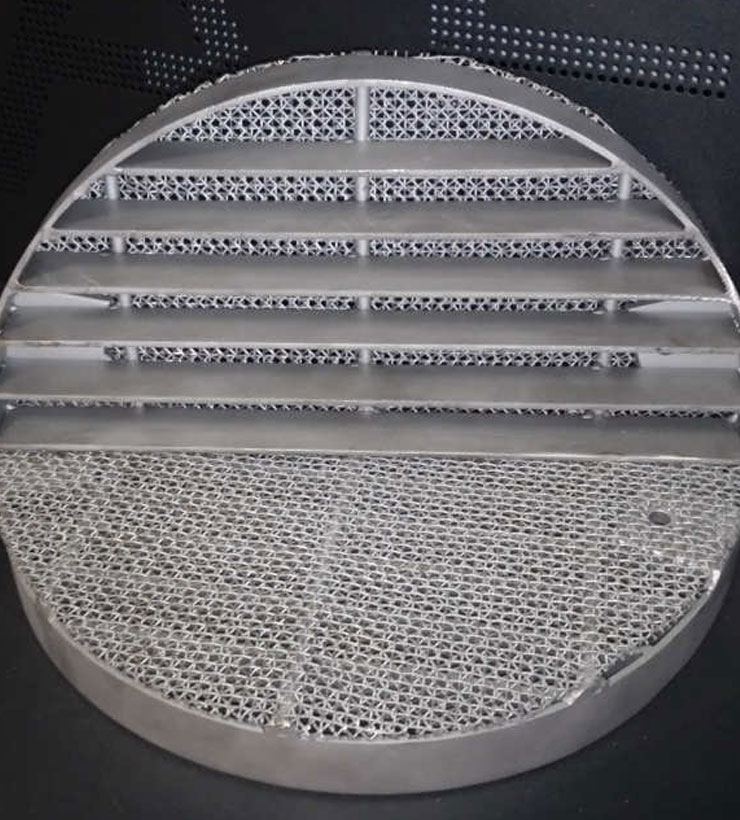

SUPPORT GRIDS

The support grids are usually installed inside the process columns to ensure, for example, structural tightness and to allow the flow to pass through the grids without having pressure drops.

The support grids can be made in various sizes and with different types of materials and, if necessary, also with different layers of metal mesh applied to the structure.

This type of grating is customizable and generally designed according to customer specifications, without neglecting the necessary mechanical stability that these support elements must have.