Internal for separators

VLV deals with the supply of internal separators: from metal mesh separators to flow distributors and lamellar packs, each product is always designed according to the specific customer needs.

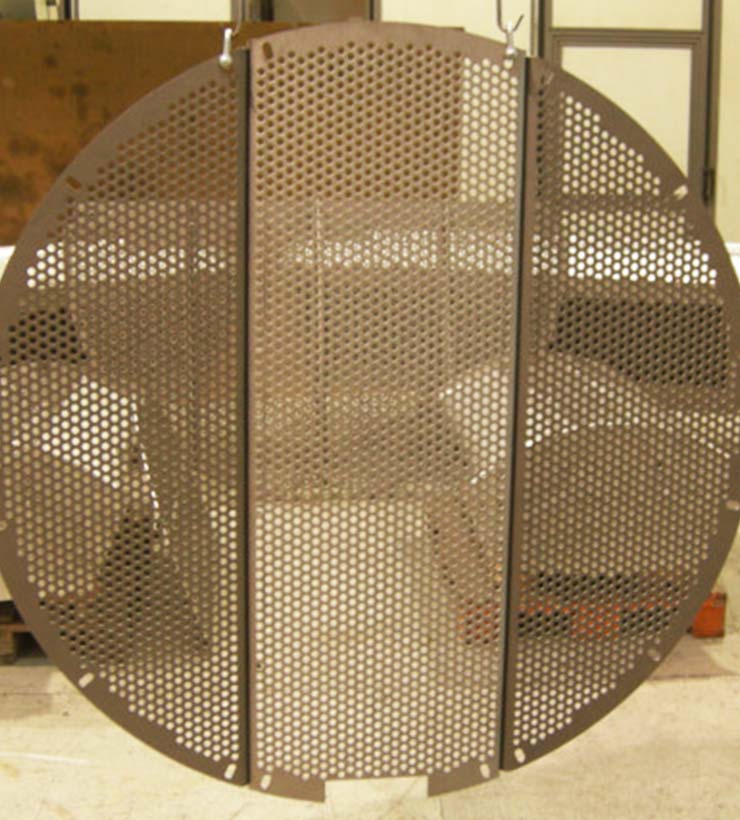

SEPARATORS IN METAL MESH

The wire mesh separator is constructed by superimposing several layers of wire mesh, until it forms an alveolar structure that has the function of trapping the drops of liquid transported by the aeriform current.

Wire mesh separators are used, for example, to purify gasses, to eliminate liquid particulates that could damage a production process, in the prevention of problems to a plant, to eliminate environmentally hazardous emissions and to recover expensive liquids that can be reused.

They are often supplied with accessories such as:

containment networks where the flow of traffic is high

extractors and fixing systems such as L and J bolts

fixing wire and support grids to hold and support the wire mesh

FLOW DISTRIBUTORS

The flow distributors are divided into:

Schoepentoeter – ST inlet device

Calming Baffles

Straightners

Gas flow rectifiers

Liquid distributors

PARALLEL PLATES PACK

This type of internal is composed of channels between long parallel plates at a fixed angle, through which you can achieve the separation of the light phase from the heavy phase with an adequate speed of the flow passage. At the exit of the package the light liquid lies above the heavy phase and can be separated by means of a weir.

The parallel plate pack for the separation of two liquids is commonly used in separators where the flow is composed of three phases:

A gas phases

A heavy liquid phase (e.g. water)

A light liquid phase (e.g. oil)

VANE PACK

Standard lamellar bundles

Standard vane pack are used to separate the liquid droplets carried by gaseous streams. They are composed of a series of lamellar profiles including the gas, passing and changing direction, impacts with the slats. The droplets of liquid slide along the vanes and are drained by a tube at the bottom of the tank.

High performance lamellar bundles

To achieve even higher performance, you can apply a metal sock agglomerator to the reed valve pack, which allows the droplets to increase their size and reach the reed valve pack with the correct speed and diameter.

W bank

If the priority is the reduction of the length of the tank then the W bank is the optimal choice. Its “V” shape allows, with a half pack length, to obtain a sufficient passage area to ensure the required separation efficiency while reducing, at the same time, the size of the tank. To increase the separation efficiency it is possible to apply a wire mesh agglomerator.